The principle is equally true in machines. This story shows how true teamwork enables a global SaarGummi team to succeed in robotic collaboration beyond any borders.

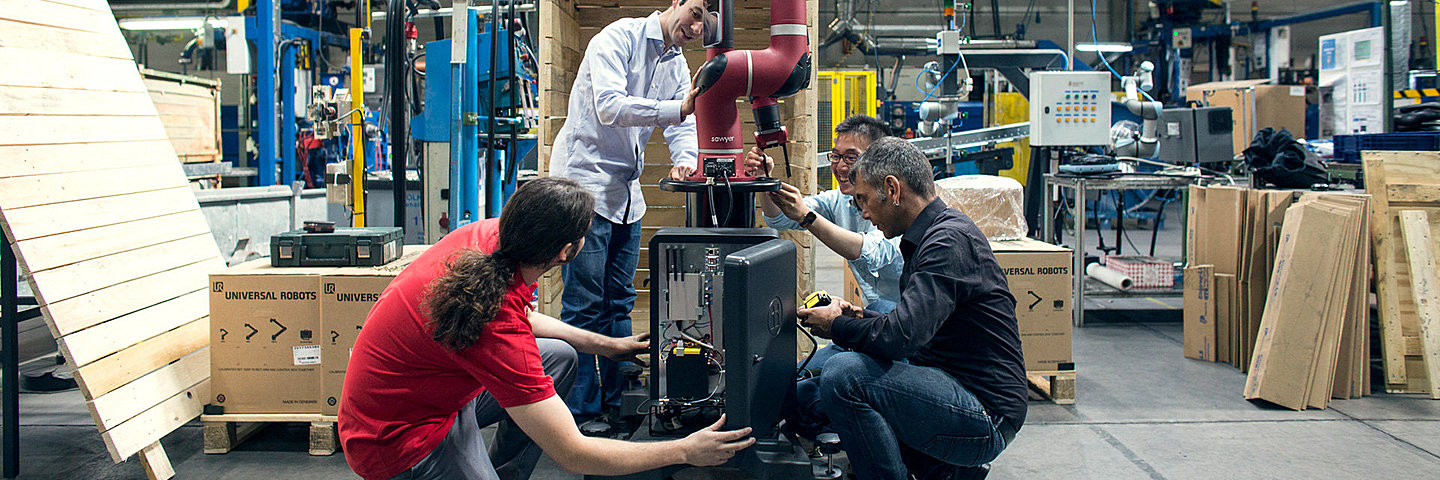

The Testing

Volker Schumacher works as an innovation scout for robotics and VR/AR at SG Neo. His passion is to look behind the surface. He loves to take things apart and to put them back together. And not only in vintage motorcycles and specialty cars in his leisure time...

Volker Schumacher

Robotics & VR Innovation Scout, Global

The Preparation

The Tool

“We do more craftsmanship - handmade stuff in our company - it is less of an industrial process in my opinion“, says Volker Schumacher. The biggest advantage of this robot is the collaborative ability. That means that people can work next to it without fencing and reduced safety equipment around while you interact with it. The collaborative industrial tool doing human work perfectly matches the SaarGummi environment.

Collaboration on a daily basis is key for the global network of SG plants.

The Packing

The Travel, Madrid

The Arrival

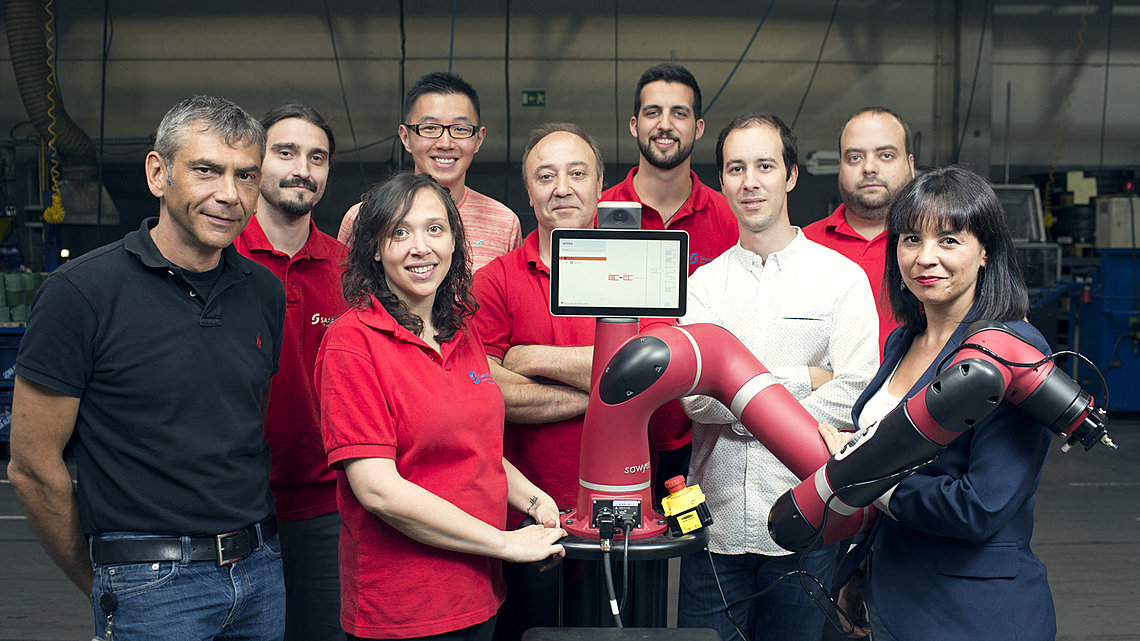

The Team

The Insight

Years before

“It all started back in 2015 when the former CEO of SG Group, Michael Lorig and myself started the discussion about how to apply automization at SaarGummi Automotive. Collaborative systems were just on the rise. I found a suitable robot manufacturer with whom we ran some tests. The biggest challenge was how to grab and channel the soft rubber materials into machine tools.”

The R&D lab from company Festo came up with the idea to copy a pneumatic muscle that flexes and relaxes. The tests were promising. Michael Lorig mentioned to Sven that the guys in Spain are also starting something with robots. The rest is history.

The Collaboration

Álvaro Jiménez Gradillas - Leader & Coordination Innovation, Spain

The Development

"We developed the original idea of Sven Müller further and implemented collaborative robots into one of our automized ITS (inline transfer splicing) machines. This concept is now also in a trial stage for one of our most complex machines: the extrusion line. The final goal is to entirely automatize the splicing process with the help of collaborative robots."

The good thing is that heavy tasks are handed over to robots while people handle the more sensitive and complex tasks such as quality management.

The Innovation team Spain

Álvaro Jiménez Gradillas

Leader & Coordination Innovation, Spain

"What I love about my job is that every day is completely different. We have project related topics with various materials and processes with new technologies like the collaborative robot. These are all entirely new frontiers for us. We now have to enter into a very creative dialog with these opportunities.”

Ángel García Gismero

Innovation Technician, Spain

Angel started as a mechanical engineer in Germany prior to working at SG Spain. He focussed ever since on automatization and machine maintenance. Instead of maintaining the same thing over and over again, he was always driven by finding new solutions to the root cause. The challenge to integrate a collaborative robot into a fully automized machine seems to him the perfect match.

"I work here for 20 years now. What I really like about this place is Juan’s continuous engagement for improvements. He came to the company and changed it into a much more personal and engaging atmosphere.”Raul Serna Pozuelo

Innovation Technician, Spain

He actually started his career as a cook and peeled onions for 6 months. Raul switched jobs to a factory that manufactured tooling for bathrooms. After 12 years being there the factory closed and he started at SaarGummi three years ago working the extrusion line.

“I like the complexity of this machine. In the innovation team now I support mainly Angel with the tooling of the robot and how the profile ends up at the robot always in the same position. I also help Patricia with the programming.

What I like the best here is that I am learning something new every day as opposed to the former factory where it was always the same.”Patricia López Alves

Robotics Programmer, Spain

Patricia worked at BMW automotive for five years prior to SaarGummi Spain. She collects and analyzes data. At the moment her focus is on the programming of the collaborative robot.

“In parallel I am in the second year of studying psychology because I am very interested in what’s going on inside humans. I love my colleagues - they make for a beautiful and great team.”

If you really want to do something, you’ll find a way. If you don’t, you’ll find excusesManuel R. Gonzalez Martín

Innovation Technician

Manuel's expertise is electronics which he implements for 15 years at the plant. The innovation team benefits greatly from this. At the moment he finds ways on how to automatically transfer parts into boxes as part of robot assisted automatization.

“I like the atmosphere in our team, the research for new technologies like cameras, software and the fact that there could be useful for any of our projects."Isabel García Galdón

Administration Innovation

Isabel started as floor operator 21 years ago, worked as an assistant in the production department and is for two years now in the Innovation team.

“I am looking into financial support for our projects. This year for example our ministry of economy co-financed our new extrusion line. We are proud of this acknowledgment from the Spanish government. I love my job: it is very satisfying for us when projects are funded and realized because of it. And I love my team.”

The best way to predict the future is to invent it

Global Teamwork

It is great to teamwork with Volker. He has worked for SG in different positions for well over 12 years. He knows all the plants and processes perfectly well. We don’t really have a lab, but the good thing is that we prepare our infrastructure in a way that innovations can be tested in real-world scenarios. Our global teamwork combines these experiences with the assets of the entire SG Group and creates leading innovations.

Special Thanks to...

Ángel García Gismero

Álvaro Jiménez Gradillas

Isabel García Galdón

Manuel R. Gonzalez Martín

Patricia Lopez Alves

Raul Serna Pozuelo