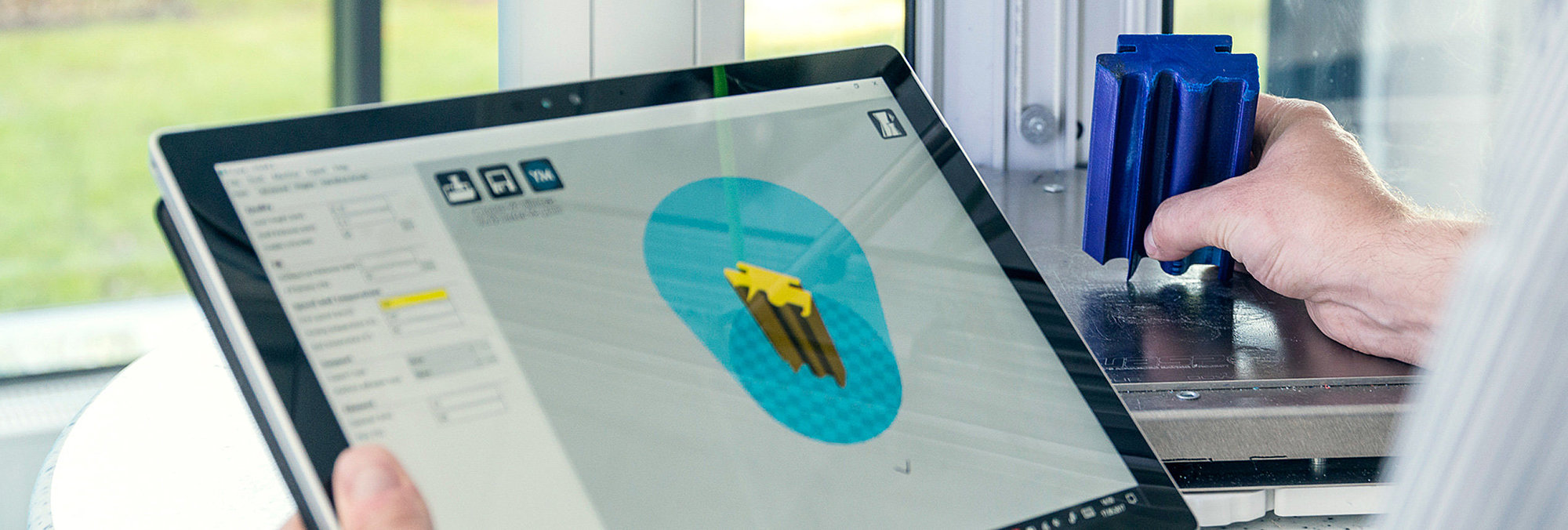

Additive manufacturing is used in metal equipment and metal tooling to correspond with customer demands for short term solution proposals.

Advantages of 3D Printing

Additive manufacturing

Additive manufacturing protects SG Group inventions, lowers costs and lifts design restrictions.

Dynamic prototyping

SaarGummi implements dynamic prototyping's response to short time to market demands.

Designed for their particular purposes

Product-related parts are manufactured individually and specifically designed for their particular purposes.

Quickly and affordably

In case of design changes the whole fixture or gauges can be now altered quickly and affordably.

Metal Tooling

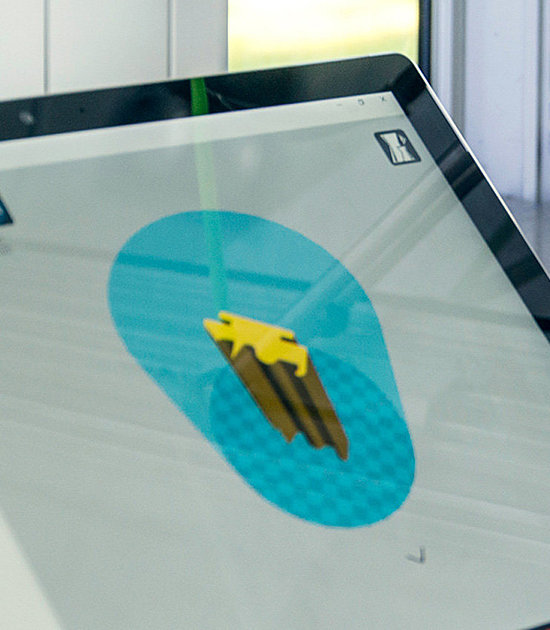

Prototyping parts with 3 D printing allows any geometry. In addition to the regular SaarGummi procedures SG Neo invites talent from all divisions to submit their ideas and designs.